Aircraft Carburetor - There are two main types of fuel induction systems in aircraft: carburetor, fuel injection. Each system has advantages and disadvantages - here's why.

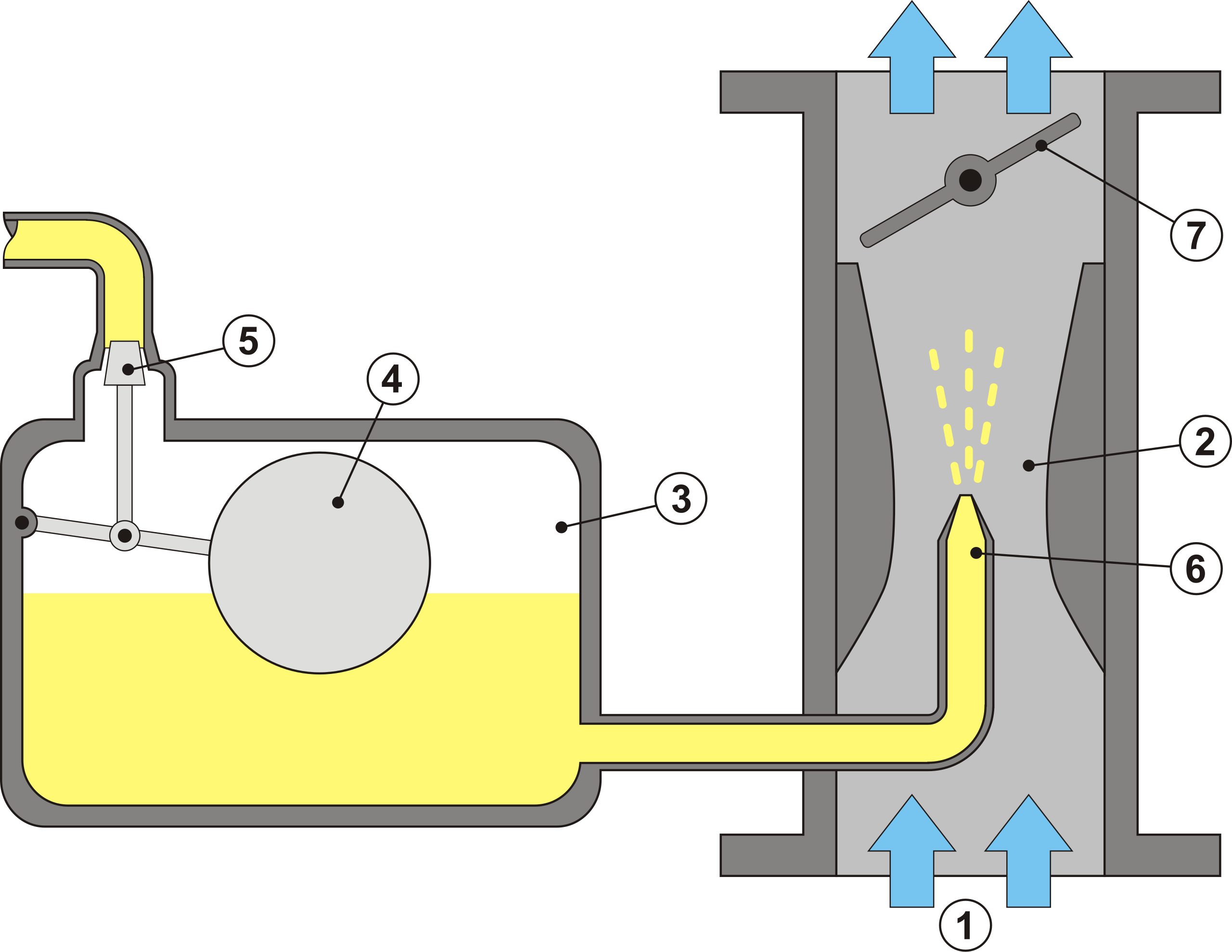

By using the Venturi effect, where the air is accelerated in the manifold due to the narrowing of the chamber, the fuel is vaporized and mixed with air before entering the engine. The volume of air flowing through the induction system is the primary way to measure fuel consumption. The throttle controls the amount of air entering the engine, while the mixture controls the amount of fuel mixed with the air.

Aircraft Carburetor

This fuel/air mixture then flows together through the induction system into the engine's cylinders, which are ignited by spark plugs to generate power. With a few extra steps (4 cycles, of course), you have engine power and you're ready to fly.

Engine Carburettor Hi Res Stock Photography And Images

The fuel injection system uses a fuel pump to push fuel through the metering system. Then, fuel flows through the injector lines for each cylinder.

The fuel injection system works a little differently than a carbureted engine because there is no air mixed with the fuel in the metering system. The servo regulator measures the air flow entering the engine and measures the fuel for the appropriate mixture.

In a cylinder, each fuel injector sprays fuel outside the cylinder head into the intake manifold. This means that your fuel vaporizes and mixes with air before it enters the cylinder.

Fuel-injected engines often have an electric fuel pump as a backup, to ensure that fuel can pass through the metering system even if the engine-driven pump fails. However, in some aircraft, the electric backup pump simply does not provide enough pressure to keep the engine running.

Ma 4 5 Marvel Schebler Carburetor Model Ma 4 5 (10 4404)

Starting cold is relatively easy for carbureted engines and fuel injection. When priming a carbureted engine, it is possible for only one priming cylinder, but it can be a number of cylinders, depending on the design of the engine.

It is more common for fuel-injected engines to fill each cylinder at once, usually using an auxiliary fuel pump.

Starting a hot fuel injection engine can be tricky. When you park a fuel-injected airplane after a flight, the fuel can vaporize in the injector lines. After you try to restart a hot engine, the cylinder may not receive the proper amount of fuel in the combustion mixture because it is in a gaseous state.

Carburetor engines are at risk of ice forming in the carburetor, which has caused hundreds of engine failures and accidents. Carburetor ice is caused by the expansion of air and vaporization of fuel in the venturi carburetor, both of which can cool the surrounding area to below freezing.

Carburetor Troubleshooting, Overhaul & Repair

Interestingly, you don't have to fly through icy conditions to get carburetor ice. High humidity or exposed humidity and temperatures between 20 and 70 degrees Fahrenheit are the most common causes of carburetor icing.

You will recognize carb ice formation by a drop in RPM with a fixed pitch propeller or a drop in manifold pressure with a constant speed propeller.

In a carbureted plane, the corrective action is to use the heat from the carb. When you turn on the heat of the carb, hot air is drawn around the exhaust and directed into the carburetor. As hot air moves in, the ice that forms will melt.

But not all news is good. As the heat from the carb melts the ice and is sent to the engine, your engine coughs, hisses and shakes until the ice melts. It's not fun to hear, but stick with it, because it will get better in the end. There have been countless NTSB reports of pilots turning off the carb heater, thinking they were making things worse, only to lose the engine quickly. You don't want to be one of those statistics.

Aircraft Carburetors And Fuel Systems: A Brief History

So when do you turn off the carb heat? Once the ice melts, the rpm and manifold pressure will increase again, the engine will run smoother and it will kill the carb heat.

If you fly a fuel-injected airplane, you don't run the risk of carbureting. However, you can get an induction glaze or a stuck filter. Just like icing can build up on your fenders, you can have ice form (from exposed moisture) on your induction intake or air filter.

Carburetor engines and fuel injection engines have their own advantages and disadvantages. But now that you know more about the differences between the two systems, flying both types and troubleshooting should be easier.

Swayne is an editor at , a certified flight instructor and first officer on the Boeing 757/767 for a major US carrier. He graduated with a degree in aviation from the University of North Dakota in 2018, holds a PIC type rating for Cessna Citation Jets (CE-525), is a former Mokulele Airlines pilot, and flew an Embraer 145 at the start of the airline. Swayne is the author of weekly articles, quizzes and lists. You can contact Swayne at swayne@ and follow his flying adventures on his YouTube channel. We and our partners use cookies to store and/or access information on these devices. We and our partners use the data for personalized advertising and content, advertising and content measurement, audience insights, and product development. Examples of processed data may be unique identifiers stored in cookies. Some partners may process your data as part of their legitimate business interests without asking for your consent. To see the purposes for which they believe they have a legitimate interest, or to object to the processing of this data, please use the link below in the list of suppliers. The consent given will only be used to process data originating from this website. If you want to change your preferences or withdraw your consent at any time, the link to do so can be found in the privacy policy accessible from the home page.

Carburetor Rebuild Kit For 947/951 Miku Ni Gp 1200r Gp800r Xl800 Gp Xl Xlt Lrv Replacement Carburetor Repair Rebuild Kit|

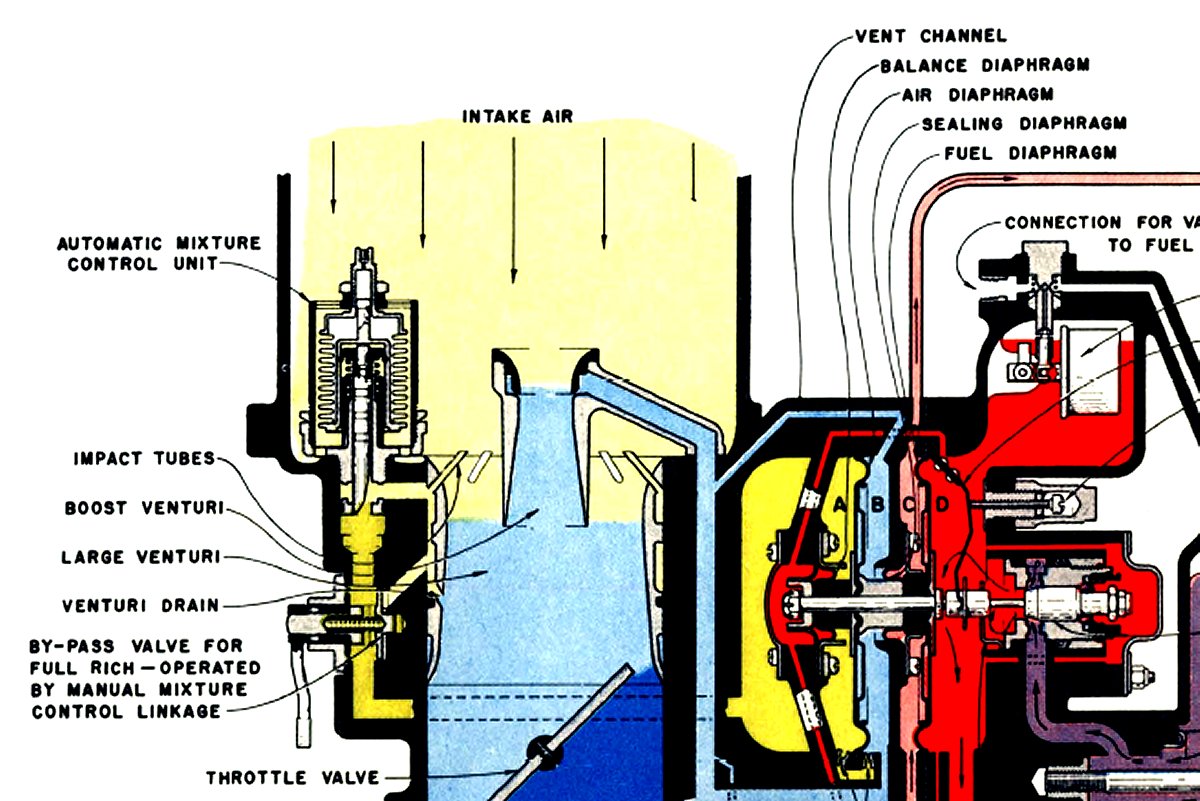

A floating carburetor essentially consists of six subsystems that control the amount of fuel output in relation to the flow of air delivered to the engine's cylinders. These systems work together to provide the engine with the correct fuel flow throughout the engine's operating range.

Float chamber mechanism system The float chamber is located between the fuel supply and the main carburetor metering system. The float chamber, or bowl, serves as a fuel tank in the carburetor. [Figure 2] This chamber provides an almost constant level of fuel to the main discharge nozzle which is usually about 1⁄8" below the hole in the main discharge nozzle. The fuel level must be kept just below the exit hole of the discharge nozzle to ensure the amount of flow proper fuel and prevents fuel from leaking from the nozzle when the engine is not running.

The fuel level in the float chamber is kept almost constant by a needle valve and a float seat. The needle seat is usually made of copper. Needle valves are made of hardened steel or may have synthetic rubber parts that fit into the seat. With no fuel in the float chamber, the float drops to the bottom of the chamber and allows the needle valve to open wide. When fuel enters the supply line, the float rises (floats in fuel) and closes the needle valve when the fuel reaches a predetermined level. When the engine is running and fuel is drawn from the float chamber, the valve occupies a central position so that the valve opening is sufficient to supply the required fuel and maintain a constant level. [Figure 1] If fuel is found leaking from the carburetor discharge nozzle when the engine is not running, it is most likely that the float needle valve and seat are leaking and need to be replaced.

With the fuel at the correct level (float chamber), the discharge rate is controlled by air velocity through the carburetor venturi tube where the pressure drop in the discharge nozzle causes fuel to flow into the intake air. Atmospheric pressure above the fuel in the float chamber forces the fuel out of the discharge nozzle. A vent or small opening at the top of the float chamber allows air to enter or exit the chamber when the fuel level rises or falls.

Holley 419 Part Of Aircraft Carburetor For Sale

Main metering system The main metering system supplies the engine with fuel at all speeds above idle and consists of:

Since the throttle valve controls the flow of air through the carburetor valve, it should be considered the main unit in the main metering system, as well as in other carburetor systems. A typical main measurement system is illustrated in Figure 3.

The fuel discharge nozzle is located on the carburetor tube so that the open end is at the throat or the narrowest part of the venturi tube. The main metering port, or jet, is placed in the fuel line between the float chamber and the discharge nozzle to restrict fuel flow when the throttle valve is wide open.

When the engine crankshaft turns with the carburetor throttle open, low pressure is created in the intake manifold acting on the air through the carburetor.

Stromberg Ps Carburetor

Stromberg aircraft carburetor manual, aircraft carburetor system, aircraft carburetor icing, aircraft carburetor repair, aircraft carburetor overhaul, aircraft carburetor parts, marvel schebler aircraft carburetor, aircraft carburetor diagram, carburetor air scoop aircraft, stromberg aircraft carburetor, carburetor aircraft engine, marvel schebler aircraft carburetor diagram